Calculating Shipping Based on Weight/Volume

Actinic offers three different types of weight-based shipping calculation. Although the settings are labelled as 'weight' they can in fact be used for any numerical measure (e.g. length), but generally, they get used for weight.

· Weight - you can enter a weight for each product in your store, and then set up Actinic to charge shipping based on the total weight of the order.

· Alternative Weight - this is an alternative measure available to use for your products, which could be used to work out volumetric shipping. There are several ways of doing this as described in the 'Volumetric Shipping' section at the end of this chapter.

· Maximum Weight - This compares the 'Weight' of the product to the 'Alternative Weight' of the product (after any 'Divide Product Weights by' factors have been applied) and the higher of the two values is used. Its particular use is with volumetric shipping and this is described in more detail below.

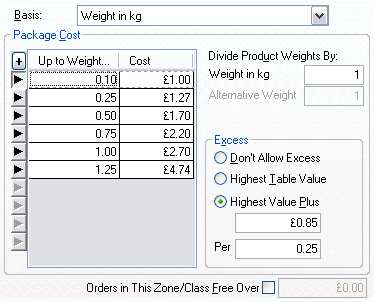

Using the 'Basis' drop down in the 'Zone/Class Tables' tab, you can decide which type of weight you want to use for each shipping class. Simply select a shipping class/zone from the white box at the left and then set the 'Basis' drop-down list accordingly.

Before you start entering values, however, you need to configure how weight is going to work within Actinic.

Weight Configuration

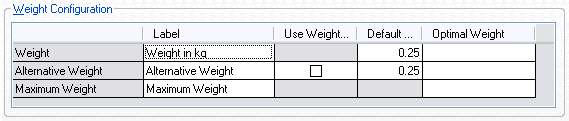

If you want to calculate shipping charges by weight or volume (or a mixture of the two) you need to enter some settings into the 'Weight Configuration' grid, which is within the 'Configuration' tab.

This grid contains three rows - 'Weight', 'Alternative Weight' and 'Maximum Weight' - and allows you to set the following settings.

|

Setting |

Description |

|

Label |

Enter how you want this type of weight to appear within Actinic. This label is used in the 'Basis' drop down list, and also in the 'Details' tabs of your products. For example, you can use this field to change 'Alternative Weight' to 'Volumetric Weight' or just 'Volume'. |

|

Use Weight if Undefined Alternative Weight only |

If you select this box, then if you leave the 'Alternative Weight' of a product blank, Actinic will use the standard 'Weight' to calculate shipping (after the shipping class division factor has been applied). |

|

Default Weight |

If you leave the 'Weight' or 'Alternative Weight' field of a product blank, then Actinic will use this value to calculate shipping charges. |

|

Optimal Weight |

The maximum weight/volume of a single package you would usually send. If the weight/volume of an order exceeds this value, then the order will be split into several equal weight 'packages' online, and shipping will be worked out on each package separately. For example if you set the optimal weight to 1kg and the total order weight is 2.4kg then the order will be considered as 3 0.8kg packages for which shipping charges are calculated and then added to form the total shipping cost. |

Entering Weights and Volumes for your Products

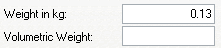

You can enter weights and volumes for your products within the 'Details' tab.

Enter a weight into the 'Weight' field (although you might have used the 'Label' column within the 'Weight Configuration' grid to change the label for this).

You can also enter an alternative weight (such as a volume or a volumetric weight) within the 'Alternative Weight' field (again, you might have used the 'Label' column within the 'Weight Configuration' grid to change the label for this).

If you want a product to be shipped within its own separately priced package, then you can select the 'Ship Separately' box here.

Setting up a Table of Values

Once you have filled in the 'Weight Configuration' grid, and entered some weights/volumes for your products (although you can do this at any time) you can go to the 'Zone/Class Tables' tab to enter some shipping charges.

You can click the '+' at the top right of the table to add new rows to the table. Enter a weight/alternative weight value in the first column and then enter a shipping cost in the second column.

For example, in the table below, orders with weights up to (and including) 1.000 will pay a shipping charge of £4.50, but orders between 1.001 and 3.000 will pay a shipping charge of £6.00.

|

Weight |

Cost |

|

1.000 |

£4.50 |

|

3.000 |

£6.00 |

What happens to orders with a value higher than 3.000 is set within the 'Excess' area (below).

Excess

This area lets you decide what to do if the order exceeds the highest 'band' you have put in the table.

|

Field |

Meaning |

|

Don't allow excess |

This option will stop the order being taken if the size of the order exceeds the highest 'Weight/Alternative Weight' you have put into the table. The customer will see a message explaining that the order exceeds the maximum and to re-select or the order cannot be taken. |

|

Take the highest value in the table |

Allows the buyer to place an order if the size of the order goes over the highest 'Weight/Alternative Weight' you have put into the table. The highest shipping cost in the table will be applied to the order. |

|

Increment highest value in table |

Allows you to charge an extra amount determined by the amount of the excess, e.g. charge an extra £1.00 per 1.000 in weight. |

Divide Product Weights

The 'Divide Product Weights By' fields can be used for two reasons:

Firstly, you can use it to calculate volumetric weights. You can read more about volumetric weights in the 'Volumetric Shipping' section at the end of this chapter. In short, your courier company may give you a number that you have to divide your product volumes by in order to get a 'volumetric weight' value for your products. This number is known as the 'Density Factor'. You can then enter the volume of each product into the 'Details' tab of each product, enter the density factor into the 'Divide Product Weights By' field, and then enter volumetric weights into the table of values.

You can also use the 'Divide By' fields if, for instance, all your products have weights entered in pounds, and your courier company uses kgs to calculate shipping. Simply enter weights in kg into the grids in the 'Zone/Class Tables' tab, and then enter a conversion factor into the 'Divide By' field. This division factor will convert your product weights from pounds to kgs.

Volumetric Shipping

Volumetric Shipping is a charging concept introduced by shipping companies to compensate when merchants ship bulky packages of low weight. Essentially packages below a certain weight density (set by your courier company) will have a 'volumetric weight' value computed, which will be higher than the package's actual weight.

A typical formula for working out the volumetric weight is:

Length x Width x Height in centimetres / 4000 = Volumetric Weight in kilograms

... where '4000' is the 'density factor'.

The weight to use is then the higher of the actual weight and the volumetric weight.

Note that some courier companies use a different 'density factor' for different areas of the world. So for example they might use '6000' for domestic addresses and '4000' for overseas.

There are several ways this can be handled within Actinic:

Method 1: Enter a single 'weight' for each product

Compute the volumetric weights and for each product work out the higher of weight and actual weight and store this in the 'Weight' field in the 'Details' tab of each product.

This is the simplest approach but is only applicable if all your shipping classes use volumetric shipping (i.e. none use plain weight) and also all shipping classes use the same density factor.

Method 2: Enter a volumetric weight for each product

Store the volumetric weights in the 'Alternative Weight' field and store the actual weights in the 'Weight' field. Then use 'Maximum Weight' as the calculation basis.

For products that clearly aren't low density (i.e. the 'Alternative Weight' will never be higher than the 'Weight') you could leave the 'Alternative Weight' field blank and set 'Alternative Weight' to 'Use Weight if Undefined' (in the 'Weight Configuration' table).

If different shipping classes have different density factors (e.g. the class you based all your volumetric weights on uses a density factor of 4000 but another class uses 6000), then you can handle this by putting the ratio of these (i.e. 1.5) in the 'Divide Product Weights By' field for the 6000 shipping class.

Method 3: Enter volumes for your products rather than volumetric weights

Put the product weight values in the 'Weight' field and the product volume values (i.e. length x width x height) in the 'Alternative Weight' field. You can then put the density division factor (e.g. the 4000 in the formula above) into the 'Divide Product Weights By' field.

Then set the shipping class to use 'Maximum Weight' as the calculation basis.

This is the most rigorous approach but it has the disadvantage of requiring a volume to be entered for all products, even ones that are clearly not low density.

Method 4: Only worry about clearly bulky items

Do as in method 3, but only fill in the volume for products that you suspect will trigger volumetric weights (i.e. they are bulky). You can then set 'Alternative Weight' to 'Use Weight if Undefined' (in the 'Weight Configuration' table).